UK manufacturing is caught between high costs and strong export demand, could investing in digital be the answer?

Facing The Future with Digitalisation And Advanced Manufacturing

UK manufacturing is caught between high costs and strong export demand, could investing in digital be the answer?

As most industries undergo a form of digital transformation, its effects are being felt by businesses everywhere.

Rapidly advancing technology has changed the expectations of consumers, who now require products and services to be available to them at any time, via the channel of their choosing.

For businesses to achieve the agility, flexibility and speed to market needed to meet customer demand, their focus has shifted to digitalisation to upgrade and transform products and processes.

This is especially true for manufacturing businesses, which support customer requests for rapidly produced parts within days and manufactured to a level of quality that will guarantee satisfaction.

Given that the industry finds itself facing increasing pressure, there is a sense of uncertainty clouding the future of manufacturing.

A mixed picture

Toward the end of 2016, almost half of the manufacturing executives surveyed by EEF, the Engineers Employers Federation, anticipated a “bumpy ride” during 2017. According to the organisation’s CEO, Terry Scuoler, they would be “forced to navigate uncertainty, unpredictable economic conditions, and a number of risks that have been amplified by Brexit.”

In contrast, the ONS published its UK index of production in late 2016, revealing a growth in output of more than 2%. Shortly after, the Confederation of British Industry (CBI) reported an improvement in manufacturing order books in the three months to February 2017, achieving their highest level in two years.

However, with recent figures from IHS Markit showing activity in the manufacturing sector as having slowed to a four month low in March 2017, these various reports clearly paint a conflicting picture of success for the manufacturing industry.

Key to remaining competitive

Recognising that agility, flexibility and speed to market are key to remaining competitive, manufacturers are looking toward digitalisation and advanced manufacturing techniques to improve and transform their existing products and processes.

The latest advances in digital manufacturing has enabled production process to perform faster than ever before, allowing customers to receive components or finished parts within a matter of days of submitting a design online.

A choice of techniques

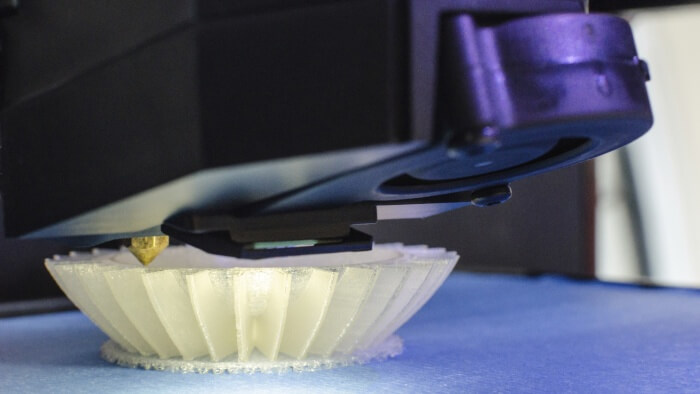

Digital manufacturing techniques, employed in services such as 3D printing or CNC machining, are now widely used by businesses in the development of prototypes and parts.

CNC machining, where computers are used to control high-speed milling and turning tools, is a popular choice with those businesses looking to manufacture parts for industrial and commercial equipment and machinery.

For projects with more complex technical requirements or part geometries, 3D printing tends to be the most suitable option. Indeed, advances in 3D printing technology now permits businesses to completely reimagine the way in which components can be designed and finished.

Combining the two processes can also offer additional advantages. For example, CNC machining can be employed as an add-on in order to fine-tune 3D printed objects.

By using the two processes in conjunction, manufacturers can better address more challenging design requirements, including increasingly lightweight components and products as seen in the automotive and aeronautical industries.

Embracing digitalisation

While industry reports may present an uncertain outlook for manufacturing, business leaders and practitioners continue to strive to improve their services in order to meet the ever-evolving demands from customer.

By embracing digitalisation and taking on board the latest developments in advanced manufacturing techniques, the manufacturing industry is placing itself in a position from where it can face whatever the future holds with a sense of confidence.

Damian Hennessey is a director at Proto Labs.

Thanks for signing up to Minutehack alerts.

Brilliant editorials heading your way soon.

Okay, Thanks!